Browse services

How Can We Help

info@procamo.in

Procamo Impex, Shri Narsinghji industrial Estate,Yamuna Mill Road,Pratap Nagar- Vadodara-390004

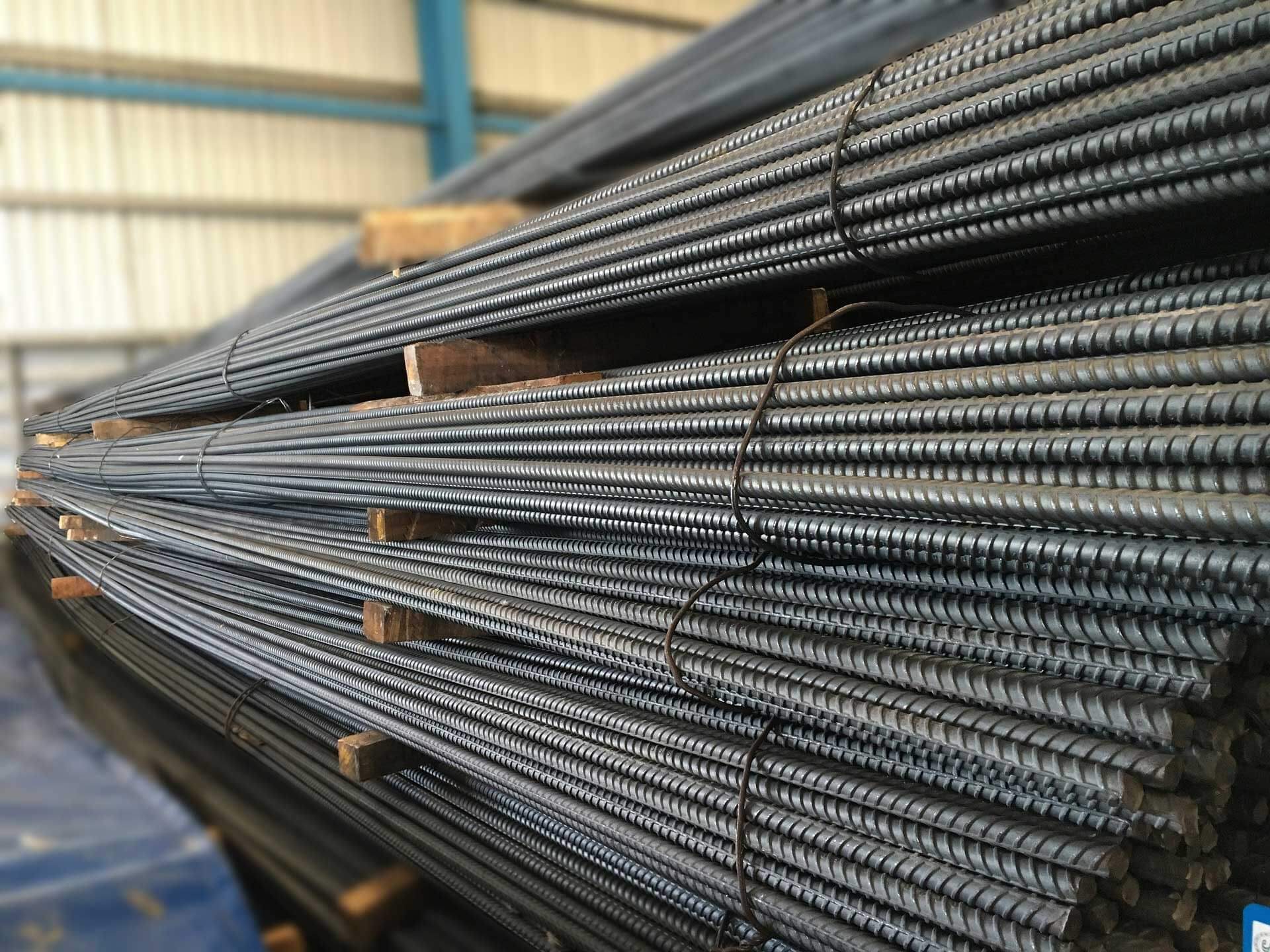

TMT Bars

TMT bars, or Thermo-Mechanically Treated bars, are high-strength reinforcement bars essential for modern construction projects. Their unique manufacturing process, involving controlled heating and rapid cooling, gives them a hard outer shell and a soft, ductile inner core. This makes them particularly well-suited for reinforced concrete structures, offering a range of benefits compared to traditional steel bars.

Key features and advantages

TMT bars offer a strong combination of high tensile strength and ductility, which is crucial for earthquake resistance and safety. The manufacturing process also enhances their resistance to rust and corrosion, especially in challenging environments. Some TMT bars include alloying elements for further corrosion protection. TMT bars can withstand high temperatures without losing structural integrity. Their ribbed surface provides excellent bonding with concrete, increasing stability. Due to their composition, they are easy to weld and bend without compromising strength or ductility. While the initial cost may be slightly higher, their longevity makes them cost-effective in the long term. They are also relatively lightweight, aiding transport and handling.

Manufacturing process

The production involves selecting high-quality steel billets, hot rolling them at high temperatures, and then rapidly cooling the surface with water (quenching). This creates a hard outer layer and a hot inner core. The heat from the core then tempers the outer layer. Finally, atmospheric cooling allows the core to become soft and ductile. This process results in a bar with a tough outer layer and a flexible core.

Grades and sizes

TMT bars are available in various grades based on their minimum yield strength:

Fe415: For residential and small commercial projects.

Fe500: Used in general construction and high-rise buildings.

Fe500D: Enhanced ductility for earthquake-prone regions.

Fe550: For industrial buildings and infrastructure requiring higher strength.

Fe550D: Higher strength and ductility for critical infrastructure in seismic zones.

Fe600: The highest grade, for specialized applications demanding exceptional strength.

Common diameters range from 8 mm to 40 mm.

Applications

TMT bars are used in a wide range of construction projects, including residential and commercial buildings, high-rise structures, bridges, dams, industrial facilities, roads, and marine structures.

Choosing the right TMT bar

When selecting TMT bars, consider the required strength, environmental conditions (especially corrosion risk), and seismic needs. Look for certifications and quality testing, ensuring compliance with standards like IS 1786:2008 in India.

Choose reputable brands with reliable customer service. Consulting with construction professionals can help ensure the right choice for the project’s strength, safety, and longevity.